HYMC provides various calendering-related production equipment in rubber production equipment, from the front train feeding/mixing/extrusion/banbury mixers/calender to the rear train of automated winding equipment!

HYMC provides various calendering-related production equipment in plastic production equipment, from the front train feeding/mixing/extrusion/banbury mixer/calender to the rear train automated winding and laminating equipment!

In terms of carbon fiber production equipment, HYMC provides carbon fiber prepreg related production equipment from the precision resin coating equipment/precision carbon fiber impregnation equipment to thermoplastic related production equipment. Applicable industries include aerospace technology (aircraft, aircraft seats), automotive components (carbon fiber, seats), green energy (windmills-generators), various sports equipment (bicycles, clubs, rackets, bats)...etc.

HYMC's electronic production equipment can provide various roll-to-roll related production processes such as roll pressing/laminating/stretching/coating/impregnating/drying, as well as pre-preparation and post-processing related processes for electronic-grade glass fiber & copper foil related processes, HYMC able to provide precisely & automate solutions. Applicable industries include IC circuit boards (mobile phones, computers, etc., 3C products) and lithium batteries.

HYMC's multi-layer composite material production equipment can provide roll pressing/laminating/stretching/coating/impregnating/drying various roll-to-roll related production processes. The processes of lithium battery roll pressing and isolation film stretching equipment are both able to provide complete solutions, and applicable industries include lithium batteries (multi-layer lamination), isolation films, solar cells, artificial leather (car chairs, etc., raincoats, curtains, canvas...etc.).

With more than 70 years of manufacturing experience, HYMC can provide customers with professional advice, planning & consulting on roll pressing/ calendaring/laminating/stretching/coating/impregnating/drying various roll-to-roll related production processes. The applicable industries are mobile phones (gloss-enhancing film), batteries (isolation film), various roll-to-roll film production equipment, and front and rear automation equipment planning.

ABOUT HYMC

Hsin Yin Machinery (HYMC) was established in 1954 and consists of three specialized factories to meet customer needs.

HYMC provides a range of equipment, from traditional machines to precise, high-tech industrial production solutions. Our process encompasses research and development, production, and final assembly.

INTEGRATION

OF EXPERIENCE

AUTOMATION

INTEGRATION

CUSTOMIZATION

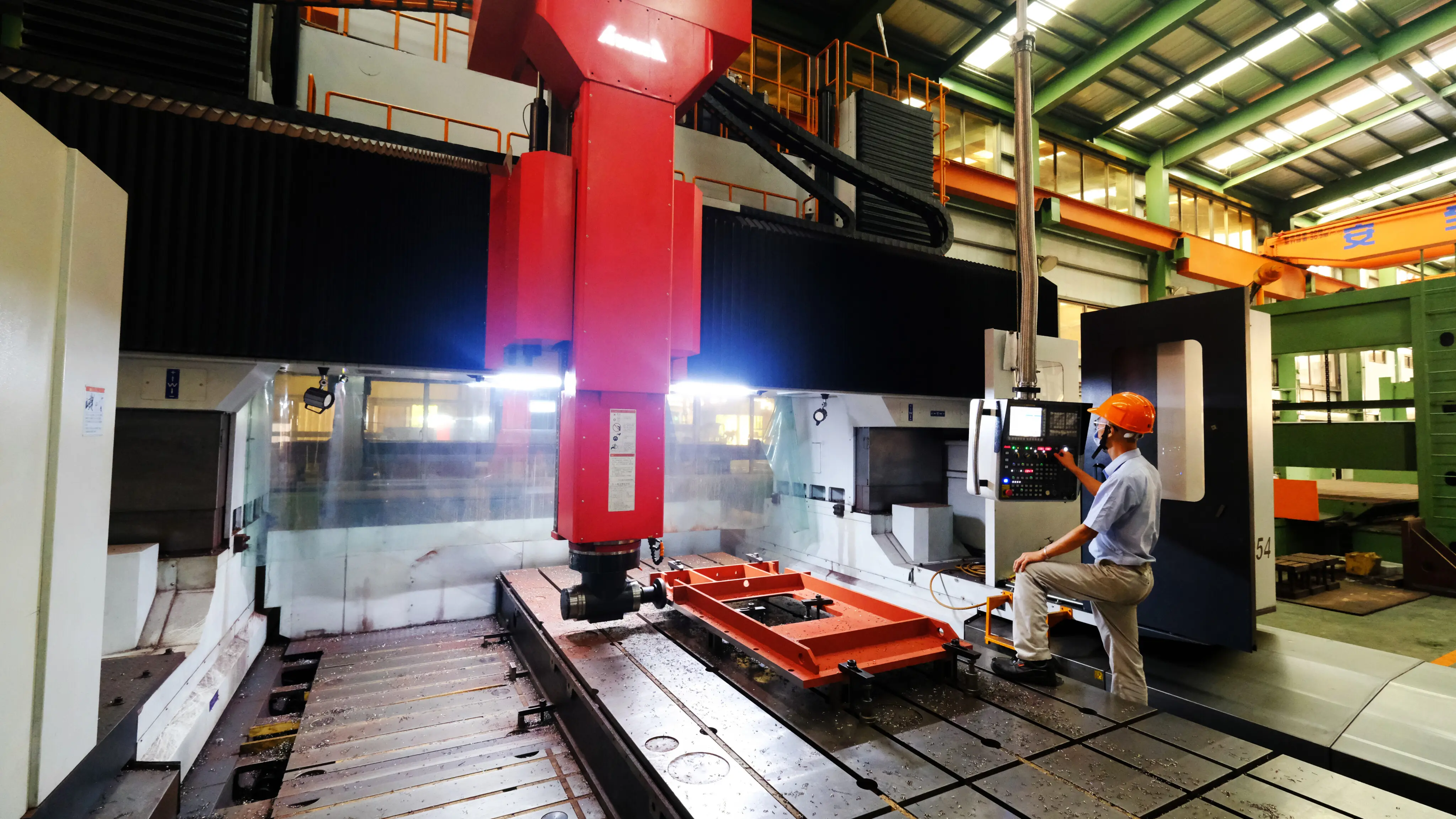

Professional technicians must carefully inspect every step, from design and welding to processing and electrical control.

From concept to blueprint, we deliver precise, innovative, and efficient solutions.

Carefully chosen materials are cut with precision, ensuring quality and accuracy.

Automated processes and expert oversight ensure consistency and performance.

Electrical systems are rigorously tested for stability, intelligence, and adaptability.

Precise assembly and fine-tuning ensure stable, safe, and high-performance machines.